From an operational standpoint, maintaining safety, efficiency, and protecting of assets in industrial settings is critical and needs to be conducted in such a manner which prioritizes equipment and worker safety. The protection boundaries in the systems are no longer just physical, but also automated and synchronized with digital frameworks to provide prompt surveillance, access privileges, and controlled predictive maintenance for equipment and digital locks. As for B2B companies, the trust and compliance attained from reliable industrial hardware suppliers assures operational trust and long-term benefits. This manuscript aims to discuss how Industrial locks have transformed with technology, their applications, and innovative patterns alongside precautions for active adoption and deployment of safety systems.

Industrial Lock: a lock and modern manufactures perspective

padlocks, combination locks and keys helped to unlock and secure most basic doors, panels and enclosures during that early phase of contemporary industrialisation. Such basic security systems are reliable yet, each of the mechanical locks comes with its own defects as a potential weak strategy, such as, ease of duplication, absence of access logs, and weak tact and follow up systems.

To keep up with the latest innovations in smart manufacturing, industries have leaned toward automated solutions like electronic locks. They now operate remotely with features like automated digital keypads, wireless connections, biometrics, RFID cards, and real-time monitoring. B2B firms have an added advantage as they can now improve their operational oversight and security, which in turn helps them in compliance with safety regulations and lowers chances for machines to be accessed without clearance.

Use Cases of Industrial Locks in B2B Sectors

Industrial locks are vital for B2B firms in the following use cases:

- Electrical cabinets and control panels: Sensitive electrical systems and devices are protected by avoiding unnecessary interventions as well as system failures which can be caused by these pieces of equipment.

- Industrial ovens and processing equipment: Personnel and the overall product quality are protected by preventing exposure to high temperatures. Parts of the industrial oven system with reliable quality and compatibility are supported.

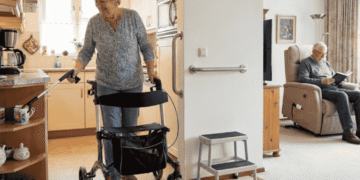

- Warehouse and storage facilities: Inventory and dangerous materials are kept safe with the assistance of smart locks, which limits access to authorized personnel.

- Laboratories and research facilities: Sensitive research and data can be protected as super user access ensures the information remains uncompromised.

- Heavy machines and production lines: Industrial locks protect important pieces of equipment and serve to limit downtime resulting from unapproved changes and unintentional equipment use.

The integration of smart locks in industrial systems advances the value of safety, continuity of operations, and data-based security management in B2B companies.

Advantages of smart and automated industrial locks

The adoption of smart industrial locks offers multiple benefits for industrial operations.

- Remote access and management: Supervision is possible from the centralized platform. Access to the system can be moderated for multiple facilities.

- Lower equipment downtime: With smart locks, the system can be integrated with predictive maintenance systems. This will notify the teams of impending operational delays.

- Advanced access control: Electronic locks and other smart devices protect the setups from unauthorized access.

- Effortless regulatory compliance: Electronic logs along with access records reduce the burden of compliance for adequate management standards.

- Expansive operational control: Modular locks can be easily distributed across multiple machines with minimal structural alterations.

B2B companies sustain lower probabilistic tampering through enhanced operational control along with reduced theft.

Choosing the Right Hardware Supplier

In order to obtain dependable smart lock solutions, the partnership with the industrial hardware supplier must be a reputable one. Consider the following:

- Product experience: Integrated electronics and industrial locks with varying electronic types, along with environmental conditions, need to be thoroughly understood by suppliers.

- Customization capabilities: The industrial setting has one or more unique security adherence constraints, for example, temperature, humidity, and vibration. A supplier who is able to devise a tailored solution makes the equipment more useful.

- Technical assistance: Guidance for installation and troubleshooting is offered by dependable suppliers, along with support for consistent system upkeep and repair.

- Quality assurance: Durability, along with the ability to resist tampering and electronic circuitry safety, must at the very least be met by the components’ quality assurance standards.

- Supply chain reliability: Replacement parts and components for the locks need to be supplied quickly and on time, to minimize overtime and maintain the smooth running functions for industrial settings.

With the strong partnership developed with the industrial hardware supplier, the unique industrial application requirements, along with the complete reliability in the smart lock solutions offered.

Best Practices for the Implementation of Smart Industrial Locks

To reap the full benefits of automated locking systems, B2B companies need to observe thoughtful approaches during implementation:

Assess Your Security Posture

Determine the sites, equipment, and sensitive areas that need to be protected and derive the levels of risk and exposure, legal constraints, and the geographical and physical environment to determine the locks and the locking mechanism best suited for the site.

Systemically Link Other Industrial Systems

Smart locks should protectively align with the rest of the technology for the automated industry, the production scheduling software, and the heuristic-maintenance software. This will allow for the automated processes to be interwoven and for real-time supervision of processes and maintenance calls to be automated.

Cater for Murphy’s Law

No automated system is immune to breakdowns. This is why it is critical that Murphy’s law does not impede operations and that procedures for back up access through key or other means of overriding the lock is readily available.

Carry Out User and Maintenance Staff Training

Proper training is critical to understanding the lock operation and the access policies that need to be on the red carpet or the lock for the operation box. Standard training policies should be instituted to reduce the potential for error, misuse of the locks, and other compliance issues.

Care and Log Repeat Use Statistics

Smart locks need to be installed together with maintenance frames that include frequency of software updates, battery swapping, and physical servicing or watching over the locks, or other data that show the systems are not cloistered. Monitoring the active data streams and change logs ensures that the system is active and alive and operating data is not falling over.

New development in the technology used in Industrial locks

The industrial locks are still undergoing some advancements in technology and industrial demands:

- IoT-enabled locks: Companies in the B2B sector are able to manage and optimize their locks and security thanks to real-time notification logs, remote control ability and overall remote managed analytics.

- Biometric access control: The problems of key access control and the risk of unauthorized physical access are potentially solved through fragmented access and fingerprint recognition, as well as retina and facial recognition.

- Predictive security maintenance: Predictive analytics and AI enable avoidance of operational disruptions through the early identification of electronic and mechanical problems that cause wear and tear.

- Integration with smart industrial ovens and equipment: The locks that are used with industrial oven parts are still used in extreme high-temperature industrial environments without compromising on safety.

- Scalable and modular designs: Locks that are fitted to drones, new machinery and other equipment are adaptable to changes in security and flexible protocols, regardless of expanding facilities and the installation of additional machinery.

All these improvements allow B2B firms to enhance effectiveness and operational effectiveness including their security strategy which provides more efficiency.

Final Words

In conclusion, intelligent, automated technology that emphasizes security without compromising function or integrity are the core advancements in industrial locks. These locks provide advanced protection with real-time monitoring and predictive maintenance for industrial ovens, heavy machinery, electrical panels, and even warehouses.

B2B companies are provided access to operationally useful and quality locks, thanks to collaboration with an ¨industrial hardware supplier¨. Partnering with industry leaders offers the most integrated approaches to security evaluation, system merging, personnel certification, and continuous improvement, thus maximally profiting from automated locks.

With the growing digitization and interconnection in industries, smart locks will be an important factor in minimizing downtimes, enhancing security and safekeeping, and the overall safety in automated and connected operations. Advanced locks paired with certain equipment, like parts of an ¨industrial oven¨, demonstrate reliable integration and excellent performance in harsh surroundings, setting the path for robust, future-proof industrial security.